Media

The New Zealand metal recycling industry encompasses a range of businesses involved in the collection, processing, re-processing and export of metals.

Metals are infinitely recyclable, but often require processing to remove non-metallic components. The industry handles metal items of all types – it is a common misconception that the only metal items which can be recycled are those which are accepted in municipal kerbside collections.

Most recyclers offer a drop-off facility for the public to recycle their metals; depending upon weights and market prices at the time, most customers are paid for the items they bring in to recycle.

Metals are valued commodities which trade internationally. In calendar year 2024, AMR members processed over 874,000 tonnes of metal, undertaking over 725,000 individual transactions, to serve their communities across NZ. 670,000 tonnes were exported from New Zealand. (Processing is part of the value chain with some processing occurring before materials are on-sold to the final exporter.)

For dry cargo (non refrigerated), NZ has an import to export imbalance. The industry assists this by making use of the oversupply of containers in depots which reduces the number of empty containers that shipping companies must return at their own cost. Getting paid both ways helps keep the import freight rates down. Without a significant amount of return cargo, many shipping companies will avoid sending cargo to NZ and all imported goods will further increase in price.

Some interesting environmental statistics on recycling of metals:

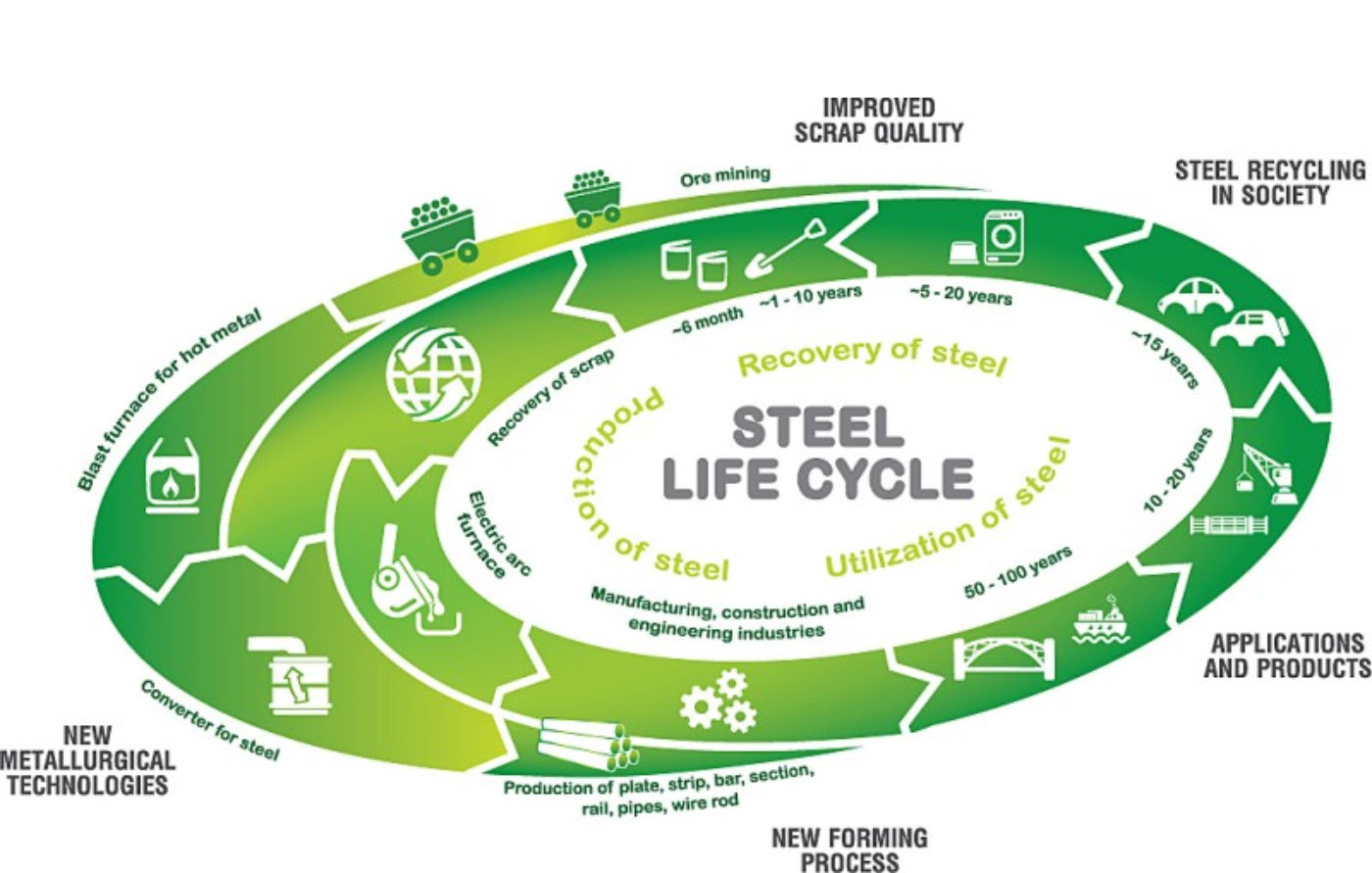

When one ton of steel is recycled, 1,133 kilograms of iron ore, 288 kilograms of coal and 54 kilograms of limestone are conserved. Recycled steel uses less energy to smelt in the manufacturing process.

When using energy to recycle aluminium it is possible to create twenty tonnes of aluminium; this is the same amount of energy that will only produce one tonne of primary aluminium from bauxite that comes out of the ground.

Automotive car batteries contain a significant amount of recycled lead, 60% of new lead is manufactured from recycled batteries world wide.

Recycling copper has the same cost as smelting ore but skips the massive environmental impact of mining the ore.

Diagram courtesy of the Australian Steel Stewardship Forum

Our President, Glen Jacobs, is the spokesperson for AMR. You can reach him by email on president@nzamr.org.nz

Our previous media releases:

Metal Recycling Association Welcomes Arc Furnace Installation at NZ Steel

23 May 2023

The NZ Association of Metal Recyclers was pleasantly surprised by the joint announcement by Government and NZ Steel about the forthcoming installation of an energy-efficient electric arc furnace at the company’s Glenbrook site. The Association notes both the potential opportunity this represents in meeting NZ’s carbon abatement goals and that the use of scrap metal in steel making is one of the best ways to achieve those goals.

“NZ has lacked the re-manufacturing capacity for scrap steel for some time,” says Joseph Gibson, the Association’s president.

“We regularly communicate with policy makers and members of the public who ask why our members export scrap steel. They do so because scrap steel is a valuable commodity required in the re-manufacture of steel products such as plate, structural steel, sheet, coil and reinforcing steel for manufacturing and construction used across the world.”

Unfortunately, the options for selling scrap steel domestically have been limited since the closure of the Pacific Steel arc furnace several years ago which was a major consumer of scrap steel.

Scrap steel is sourced from post manufacturing, infrastructure, construction, end-of-life vehicles, white goods and everyday consumer products that are recycled. The scrap steel is processed locally to meet the specifications of steel makers worldwide. Gibson says this latest development will reduce the amount of scrap steel exported given there will be a demand for scrap steel to feed the new arc furnace. Exporting of scrap steel will continue, however, as the new arc furnace is unlikely to consume enough material to absorb all New Zealands’s recycled steel.

Association members look forward to working with Government and NZ Steel in the future and to the progress of this project which will contribute toward New Zealand’s circular economy.